- GST No. 07BENPG1285H1ZE

| Business Type | Manufacturer, Exporter, Supplier |

| Condition | New |

| Application | Commercial |

| Brand | Fragma |

Preferred Buyer From

| Location | Worldwide |

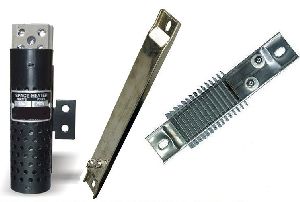

Cartridge heaters are most frequently used for heating metal parts by insertion into drilled holes. For easy installation, the heaters are made slightly undersize relative to their nominal diameter.

The majority of applications do not require maximum watt/in². Use a watt density only as high as needed. Take advantage of the safety margin provided by using ratings less than the maximum allowed. Select space heaters for most even heat pattern rather than the highest possible wattage per heater.

At medium Watt densities, general purpose drills are usually adequate for drilling holes. Typically, these result in holes .003" to .008" over the nominal size of the drill, resulting in fits of 010". 015". Of course, the tightest fit is desirable from a heat transfer standpoint, but somewhat looser fits aid in installing and removing cartridge heaters, especially long ones. Holes drilled completely through the part are recommended to facilitate removal of the heater. After drilling, clean or degrease the part to remove cutting lubricants.

Common Applications :-

- Aerospace

- Food Processing

- Food Service Equipment

- Glue Guns

- Heating Gases and Liquids

- Hot Runner Molds

- Hot Stamping

- Laminating Presses

- Medical Equipment

- Molds

- Packaging Equipment

- Plastic Extruders

- Plastic Molding

- Platens

- Scientific Equipment

- Sealing Bags

- Semi-Conductor

- Shoe Machinery

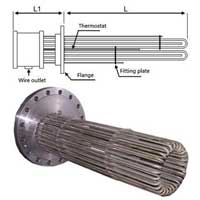

Determining Watt Density

The term "Watt density" refers to the heat flow rate or surface loading. It is the number of Watts per square inch of heated surface area. For calcualation purposes, stock cartridge heaters have a 1/4" unheated length at each end. Thus, for a 1/2" x 12" heater rated 1000 Watts, the Watt density calculation would be as follows : Watt Density = W / (Π x D x HL) Where: W= wattage = 1000 W Π = pi (3.14) D= diameter = 0.5 inch HL = Heated Length = 11.5 inch Watt Density = 1000/(3.14 x .5 x 11.5) = 55 W/in